The Brief

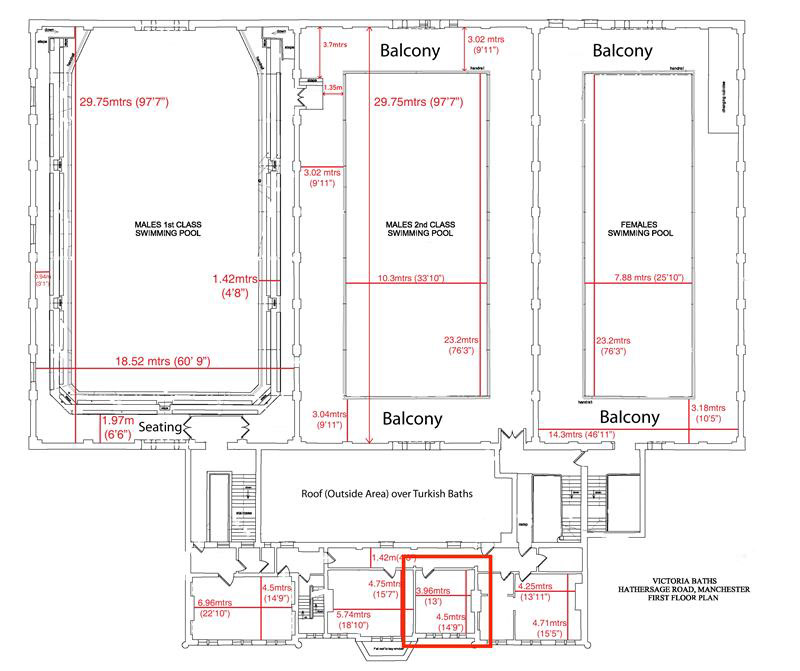

The Craft and Textiles Final year degree students are being given the opportunity to present a sample showcase of current projects. This is a 4 by 4-metre room in The Victoria Baths in Manchester (a listed building), which will serve as our area to present the work. Each student must submit 1 or 2 samples which showcases the direction of their current practice. These can focus on narrative or technical skills but must show a clear direction for development and further investigation.

I have chosen to collaborate with our lecturer Mark Mcleish and other students to design and produce the exhibition. I took on the position as one of the student project leads focusing on the fabrication of the display. Others will focus on the social media, curation and creating a Zeen.

The timescale of the project is tight with 12 days until set up and 15 until the final private view.

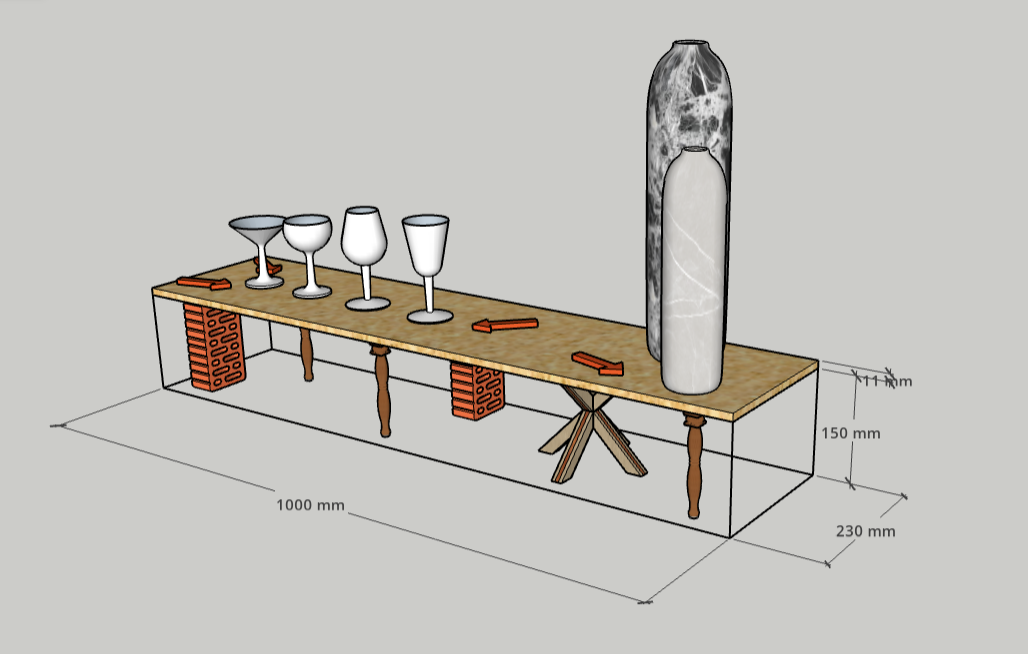

Mark has outlined his vision for the display in the room; a series of long low plinths onto which the samples will be placed. The requirements for these are 1 metre long by 9 inches wide and a maximum if 6 inches. Ideally a variety of heights will be constructed, and an overall 25 plinths are needed. The idea behind such a low plinth is to force the viewer to inspect the work closely and more actively navigate the space. Additionally, the plinth will be supported by many legs, exploring his concept of “It's Got Legs” (to have endurance and prospect). These legs will be constructed from a variety of materials and by a group of collaborating students. As the group has a varied material portfolio there will be a series of differing aesthetics and material qualities which will complement the sample which lay above.

In our first meeting we discussed that we wanted to produce the plinths at 3 varying heights off the ground: 4, 5 and 6 inches. I believe a good ratio for this is 3:7:15 and we wanted a minimum of 8 legs per plinth. This enables us to allocate differing numbers to the plinths’ curation and set up of the display. I then divided the total number evenly throughout the 10 students in the group with a goal to make three 4", six 5" and twelve 6" legs. This is a goal for our first batch, with a review 5 days into the project (3 days of workshop access is available).

In addition to the plinths, Mark has requested some arrows to be made which will guide viewers around the space and to the samples. I have delegated the design of the arrows to 2 members of the team who will produce an illustrator file which we can laser cut multiples of. My aim is to provide Mark with a sample selection of designs and materials so that he can curate a final vision and give us a specific number of arrows in correct colour and material.

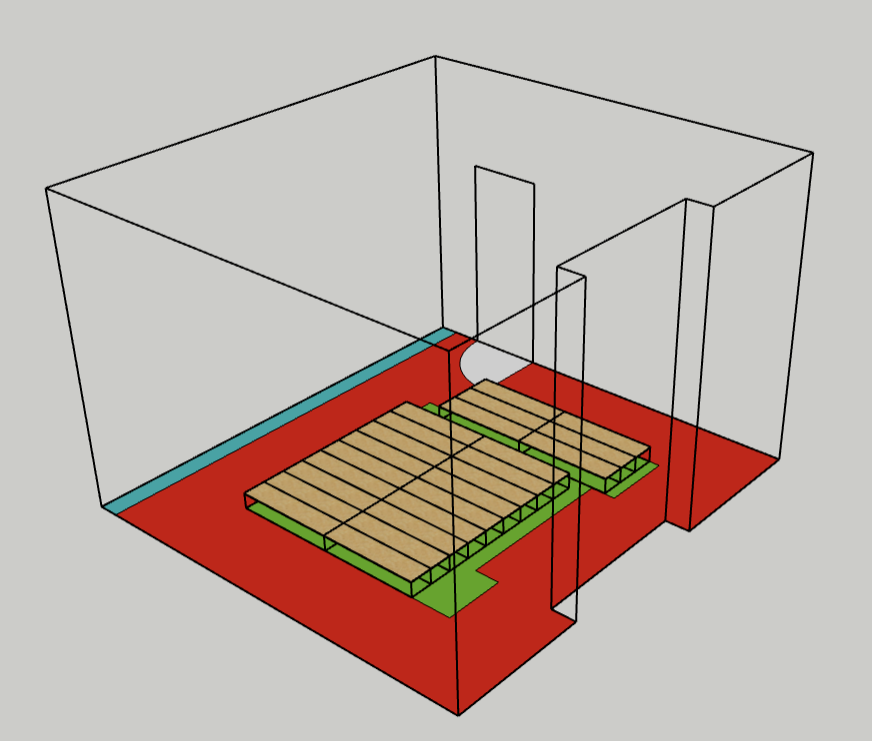

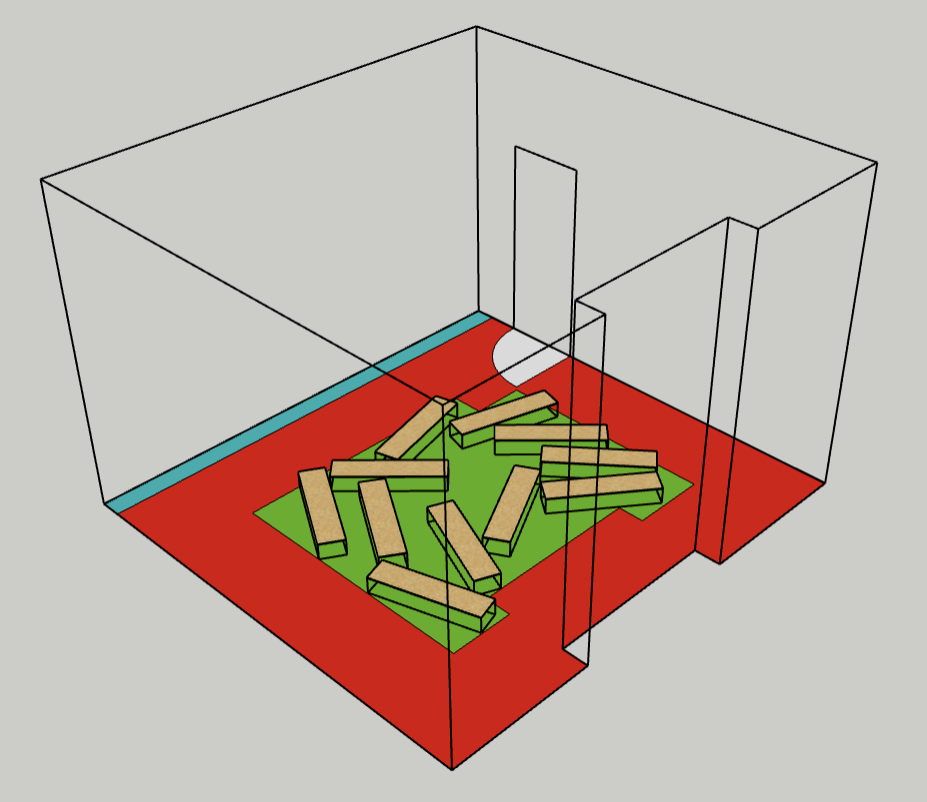

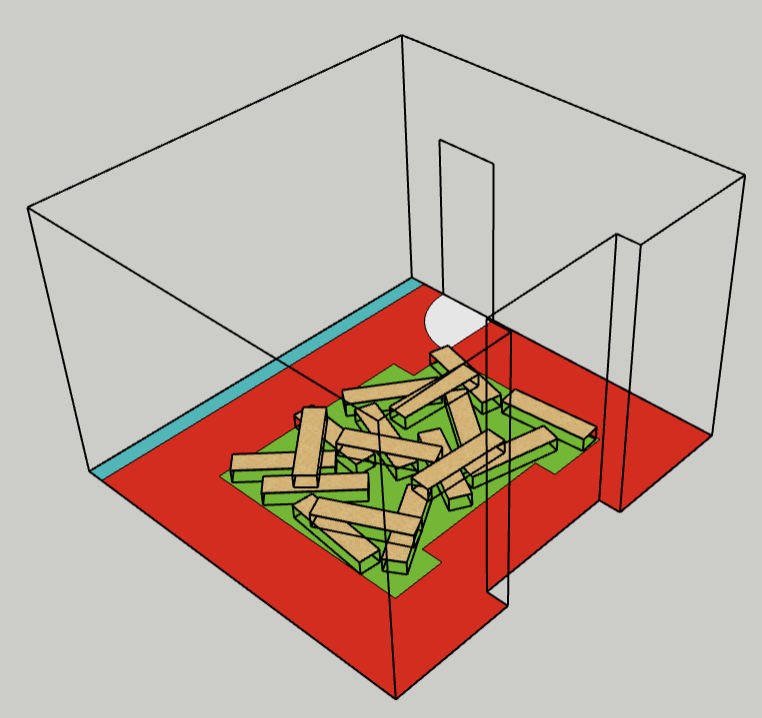

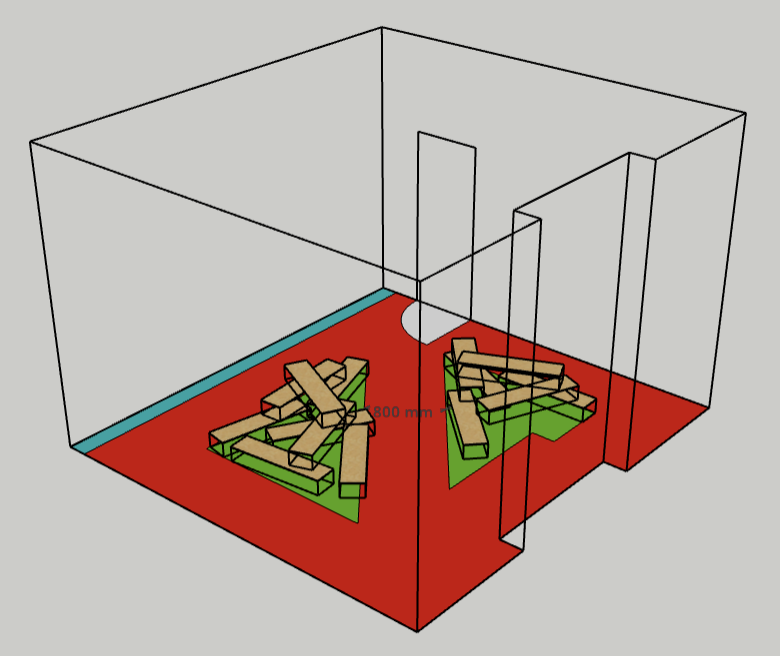

To gain an understanding and visualise the concept and measurement I created a quick mock-up of a plinth in Sketchup. I inserted simple models from the 3D warehouse to assist with communicating the visual language to the rest of the team.

Fabricating the plinths

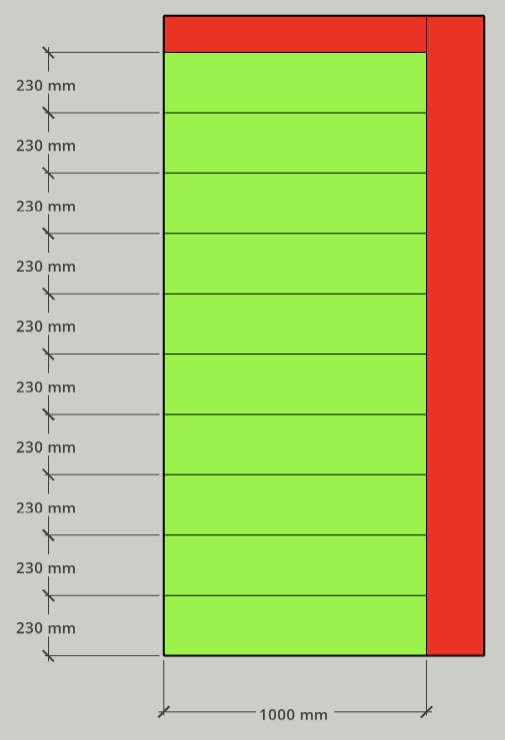

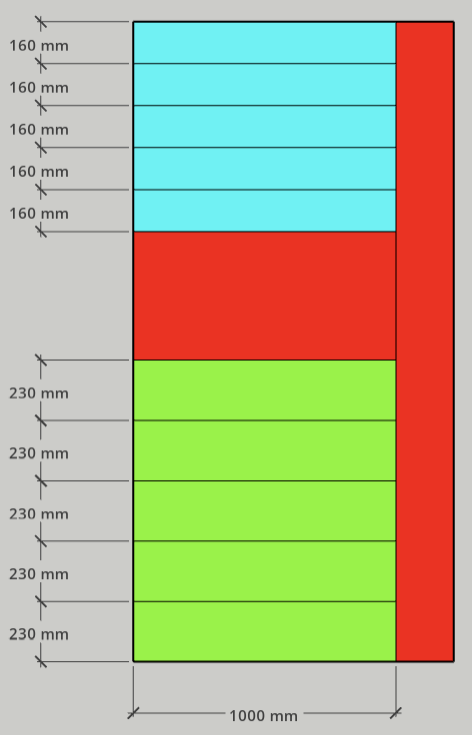

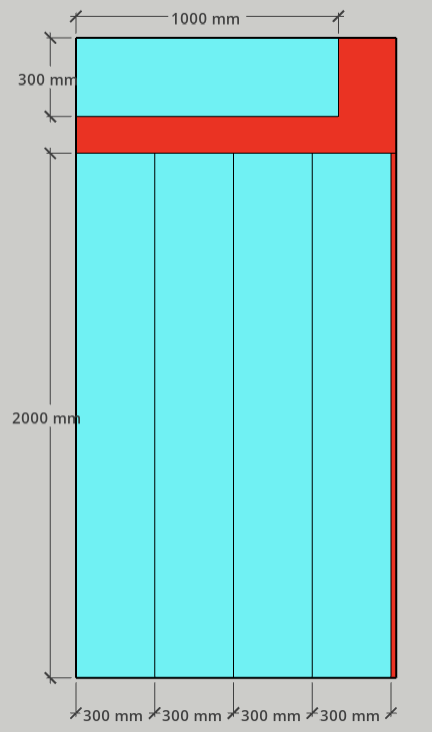

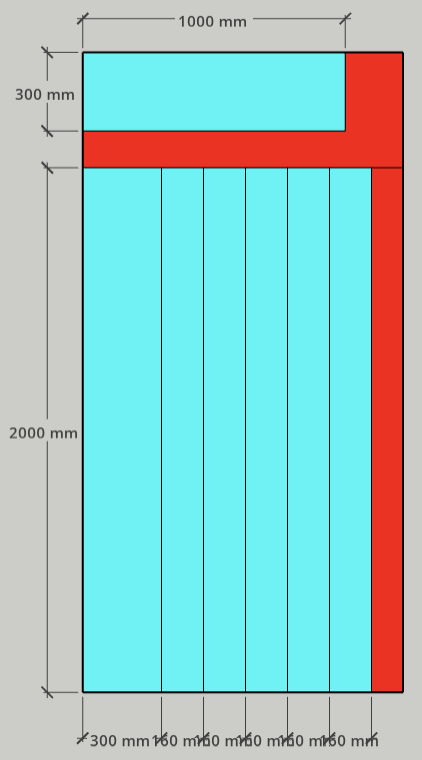

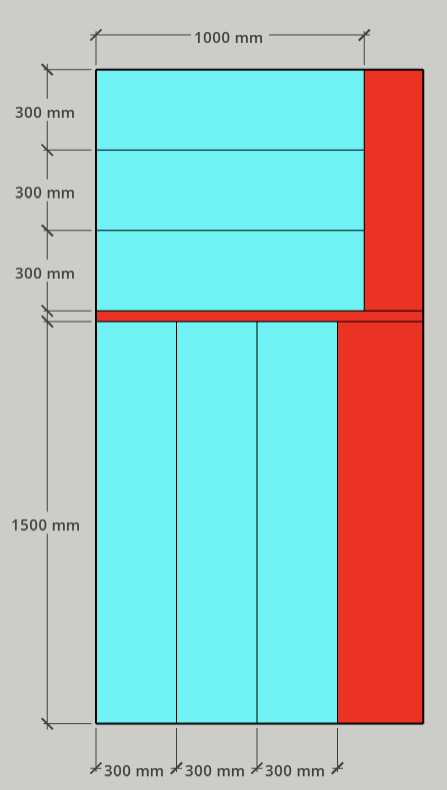

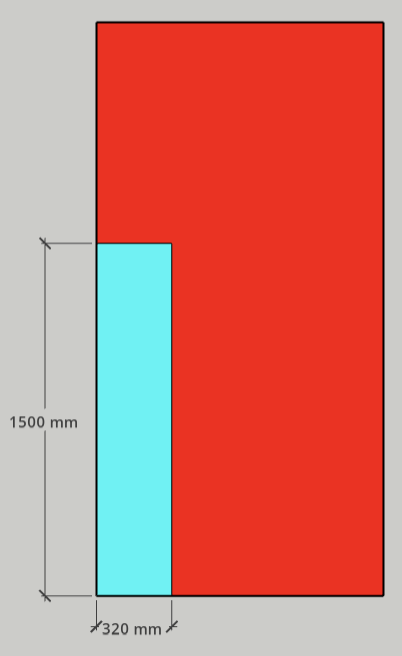

Cut list:

All from 2440x1220x11mm OBS sheets

1000x230mm (25x)

2000x300mm (5x)

2000x160mm (5x)

1500x300mm (5x)

1500x160mm (5x)

1000x300mm (5x)

1000x160mm (5x)

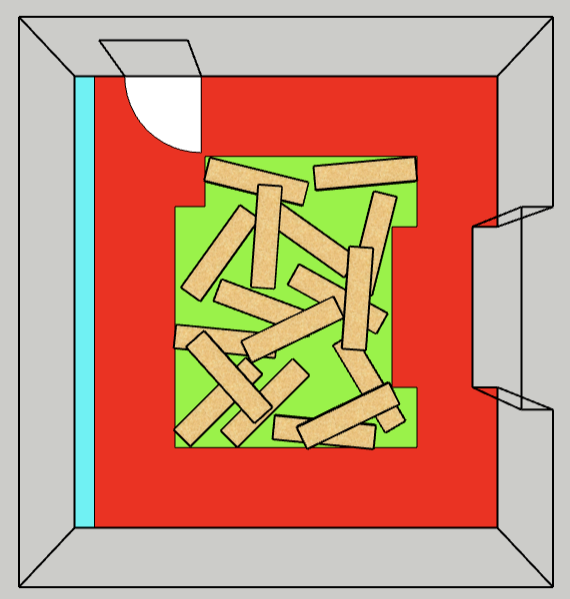

To work out how many sheets of OBS we needed I templated out the cut list onto sheets using Sketchup. I tried to tessellate the pieces so that there was as little waste as possible. The green shows the pieces required for Craft, blue for Textiles and red for waste. I had to ensure that there was enough margin surrounding the pieces for a 5mm cut line of the table saw. Additionally, I laid the pieces out so that it would be the most efficient process for the Wood department to cut.

Once they had cut the OSB sheet to size I sanded down the edges with 80 grit sandpaper to make them safe to handle, ensuring that there was a uniform and consistent finish to the cut lines.

Making my protion of the plinth legs

For my contribution to the plinth legs, I wanted to explore a range of skills and processes that I haven't had lots of experience working with or opportunity implement.

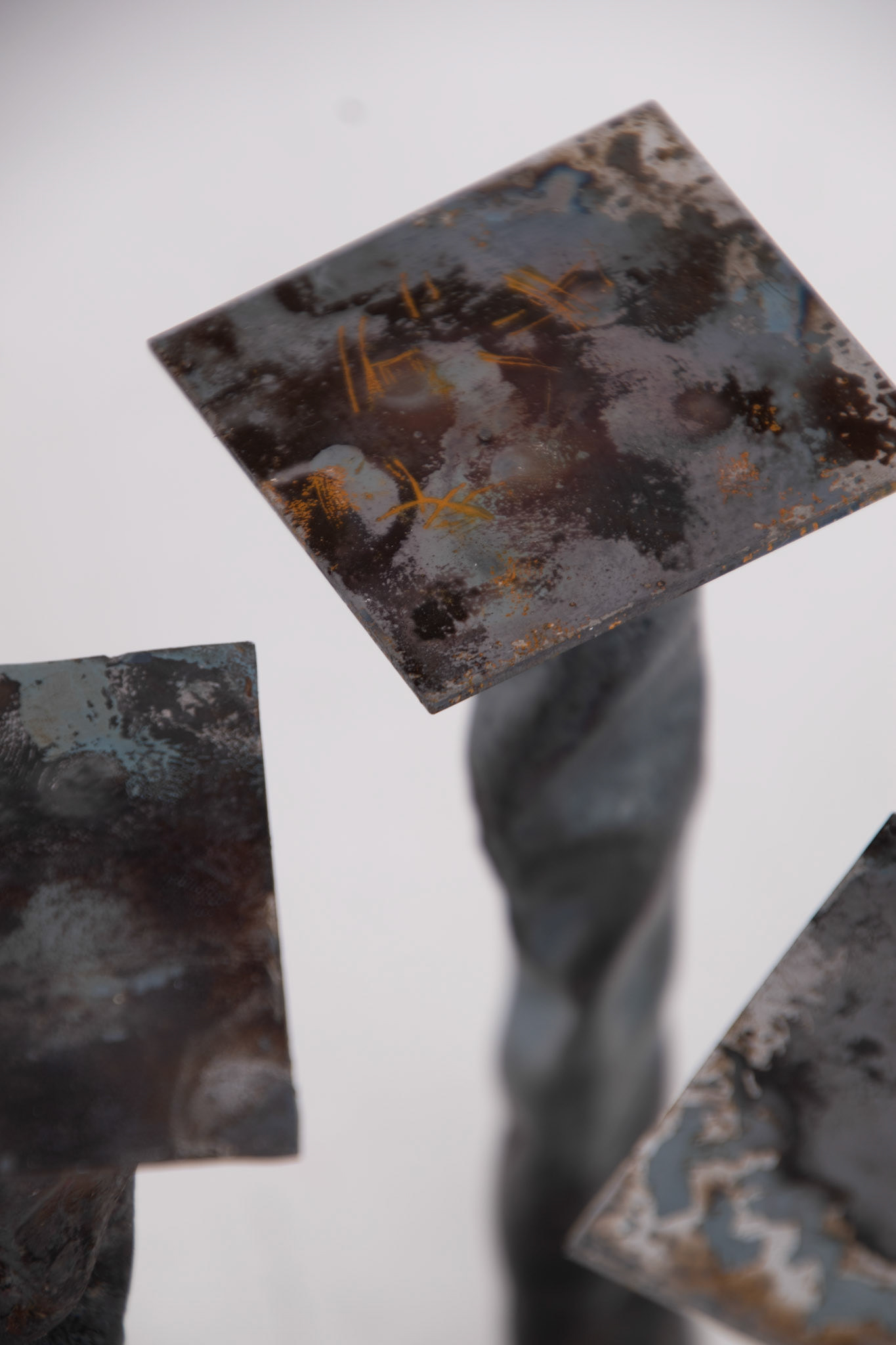

One of these processes is forging steel tube, transforming the uniform profile into a natural twisted structure. I found this process through watching inanlou_iron.art's Instagram reels. I also practiced my welding to tack 1.2mm steel sheets onto the forged steel pipes, so that the legs could be secured to the OSB.

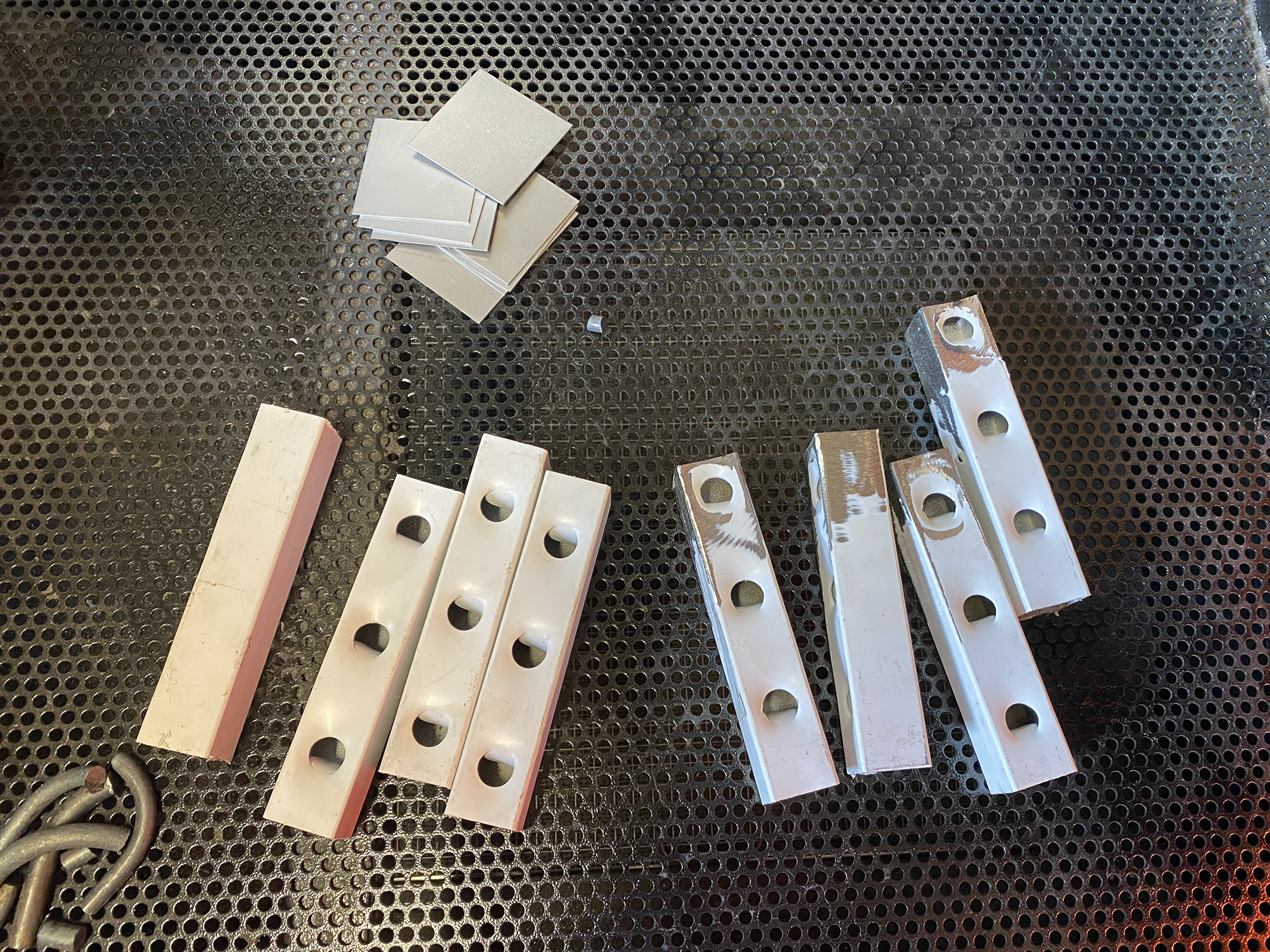

I practiced my welding further with another set of legs made from steel racking off cuts. I used an angle grinder to remove the paint so that I could weld 60mm square steel sheets onto the tops. When grinding I feathered the painted and bare steel surface finishes to create a smoother transition.

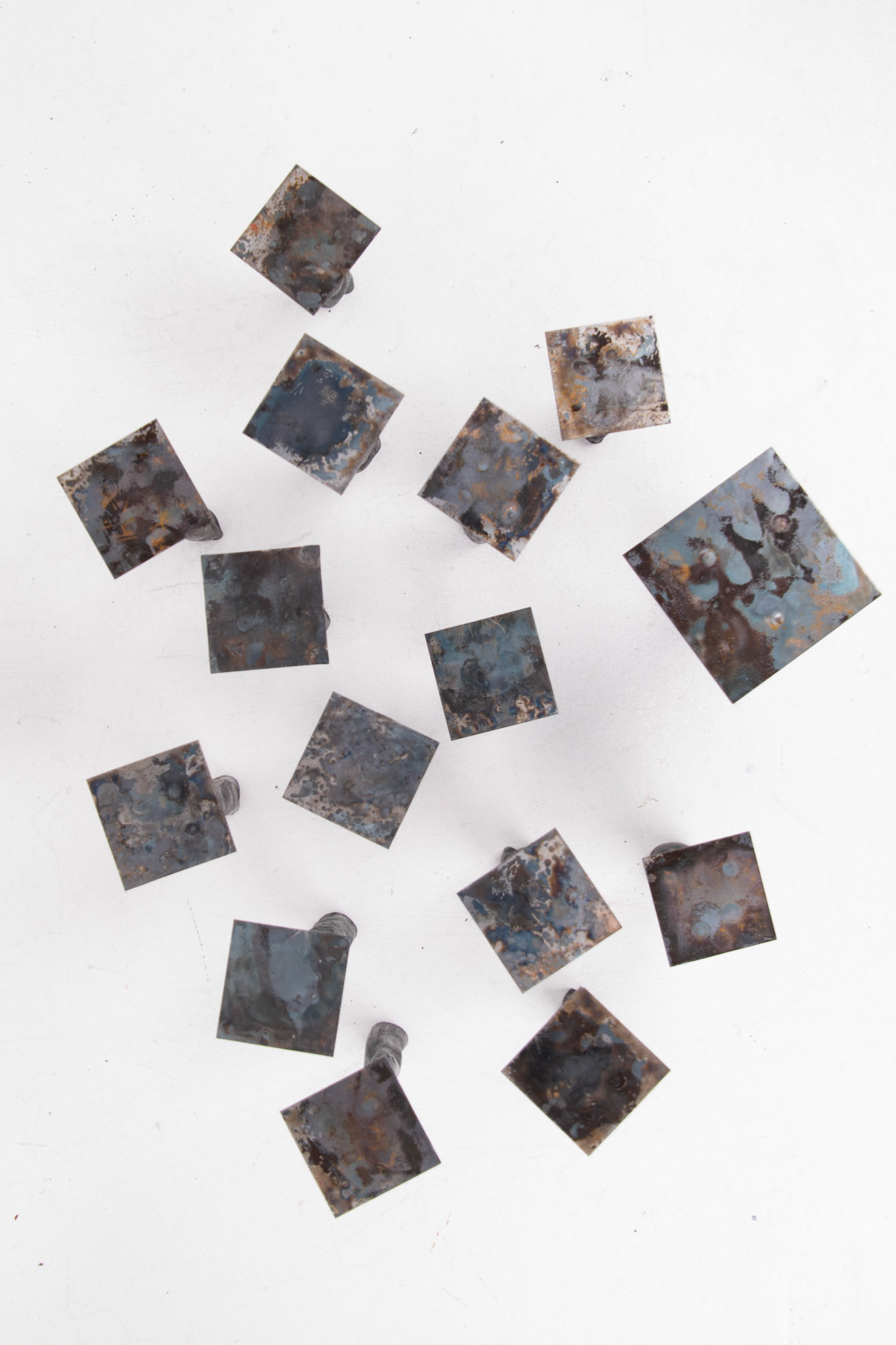

I used the Daylight studios to capture high quality photos of my work in preparation for the exhibition, to upload to my Instagram.

I went and used the Daylight studios to capture high quality photos of my work in preparation for the exhibition to upload to my Instagram.

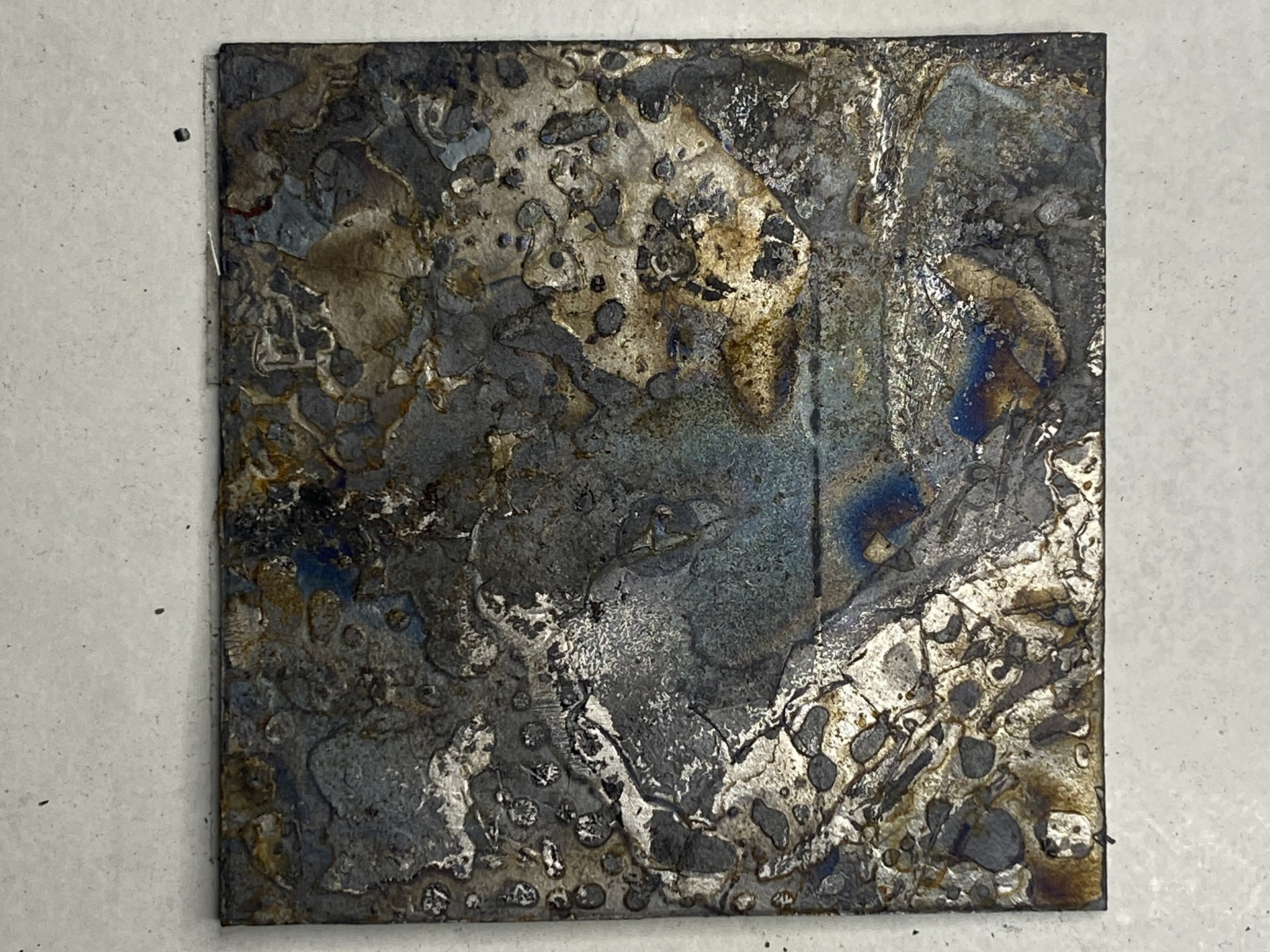

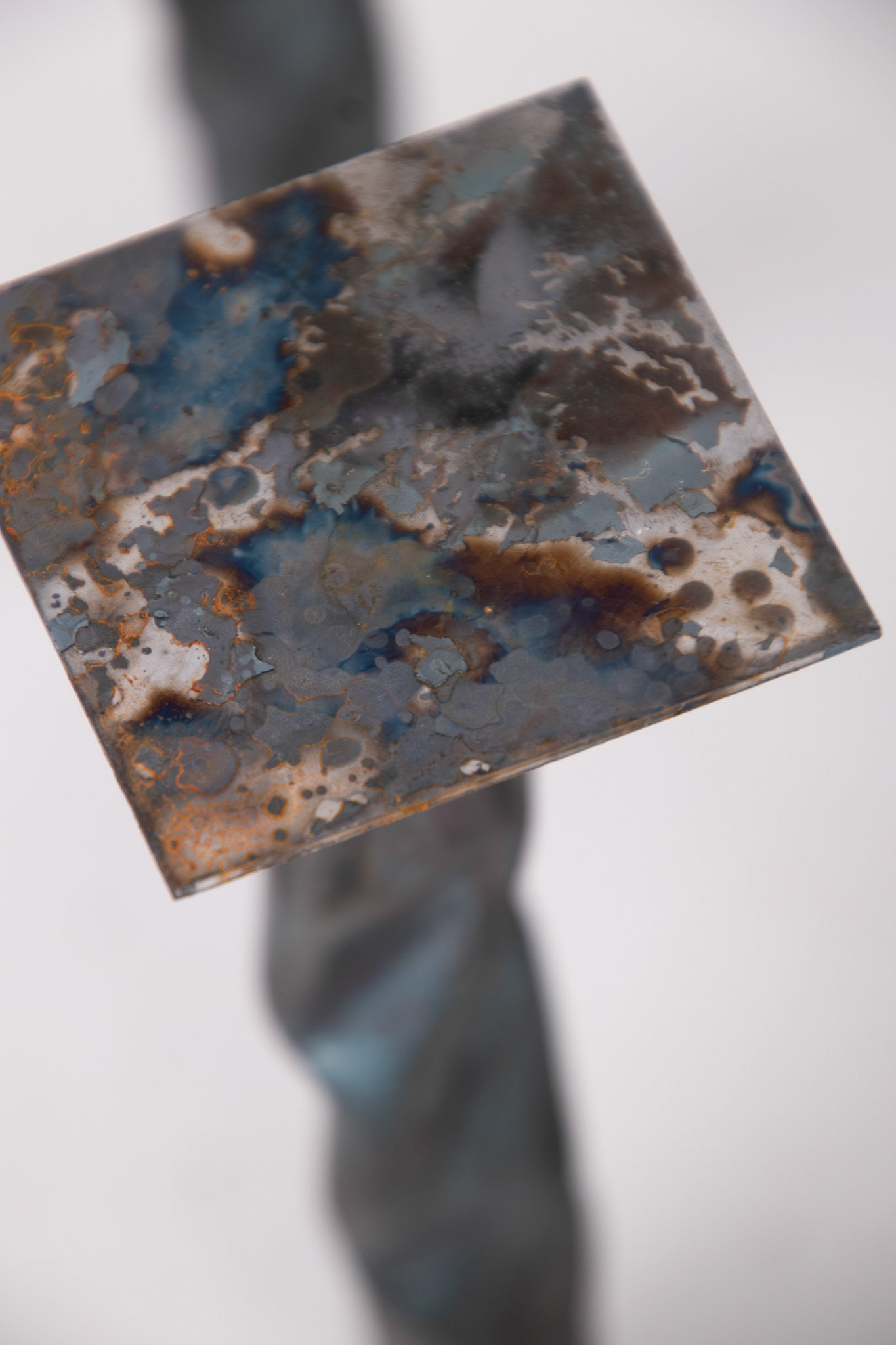

Through this photographic series I realised that an area that was most successful was the finish applied to the steel plate that I welded to the legs. In particular, I loved the variety of colours and patterns resulting from heating the piece in the forge and quenching it, and the unpredictability of the surface finish . I believe that this brings a collaboration between maker and material, and an area that I will explore further in Unit X.

I experimented with the 2 series of legs to create an initial mock-up of how they could be used to support the OSB boards.

I also began to experiment with the way my work sits on the plinths. My focus was to work out how these pieces were affected by gravity as I lay them over the edge of the boards. This is a key area that I needed to explore as the form of the mail dramatically changed when raised, as the piece expanded and contracted. This photoshoot helped me to realise that when designing my work I needed to look at how it sat both on a horizontal surface but also against the body, looking at how gravity and the support of the wearer effects the piece.

Curating the display

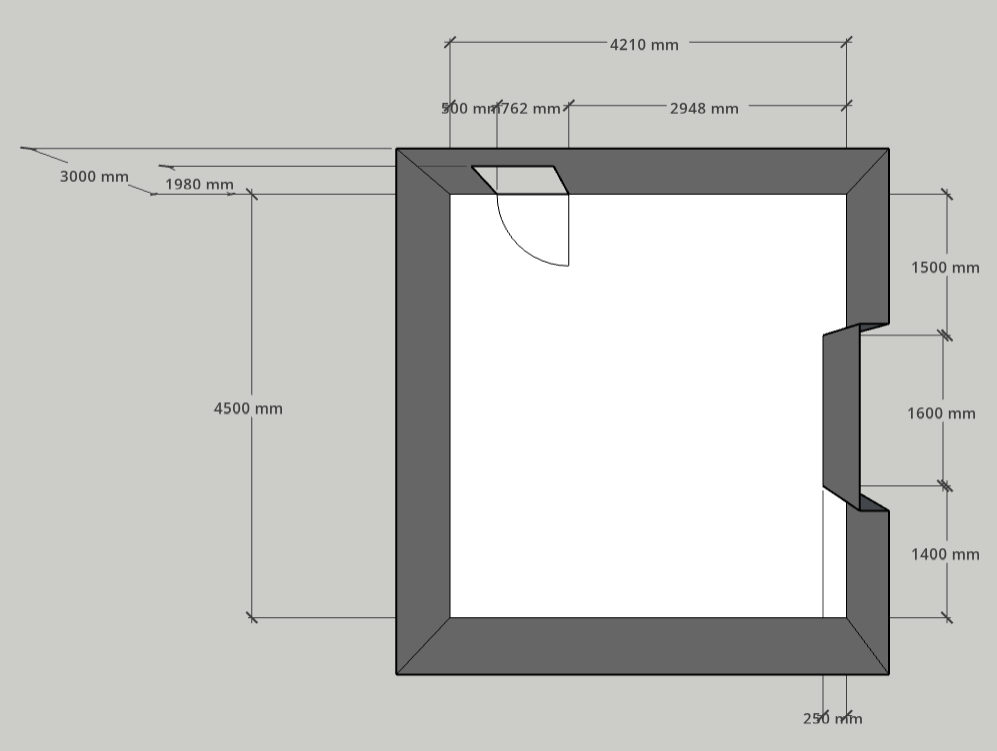

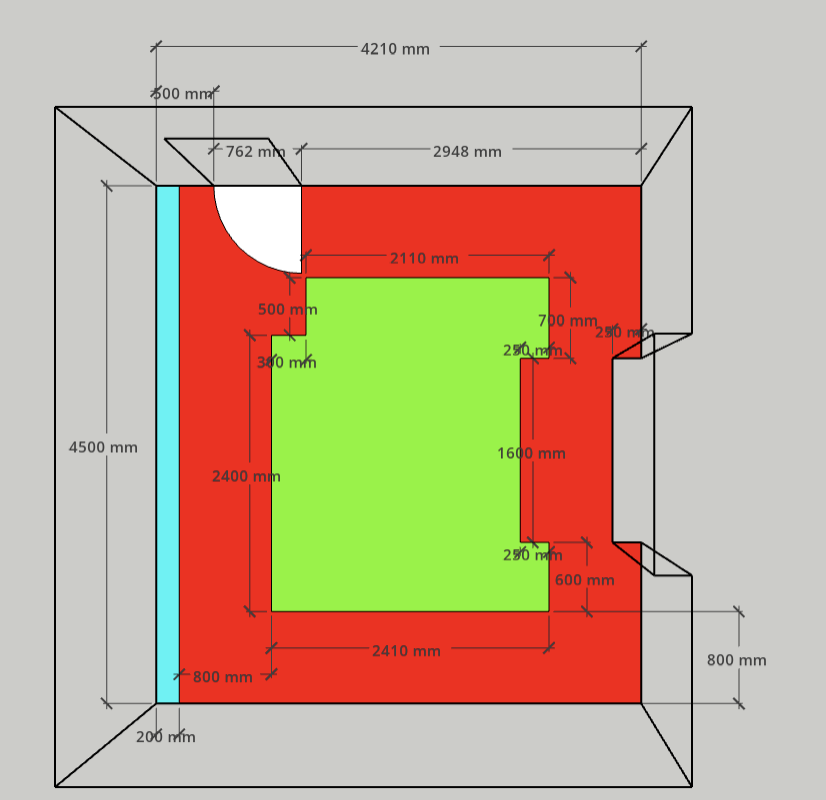

I used a combination of Fusion 360 and Sketchup to map out the rough dimensions of the room working from the floor plan above and the pictures of the room.

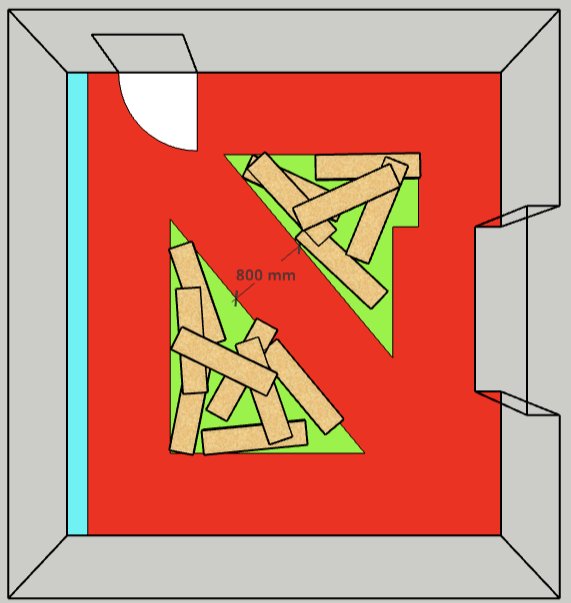

Once I had the floor plan, I added in a 800mm walkway around the room (shown in red), resulting in the central floor space being used for Craft (show in green) and one wall against which Textiles (shown in blue) will lean their work. The 800mm walkway should be enough room as there is no wheelchair access on the first floor of the venue. I did this not only to gain a feel for the size and movement around the room, but to figure out how the 25 plinths that Mark has requested will physically fit, as this was a large concern and confusion amongst many of the committee.

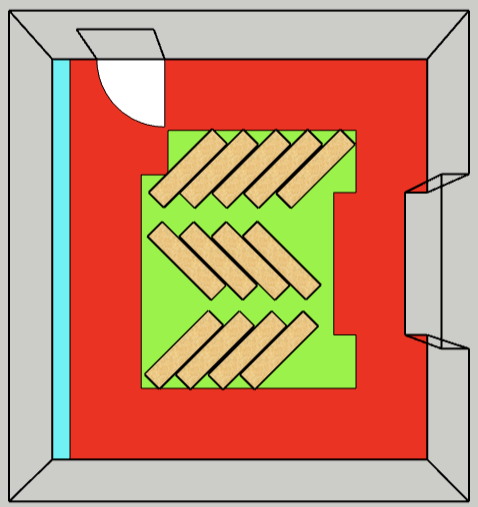

I then experimented with a series of different layouts of the plinths. First looking at a herringbone pattern to break the larger boards up. This design didn't have any movement which contrasts with the concept of potential and progression.

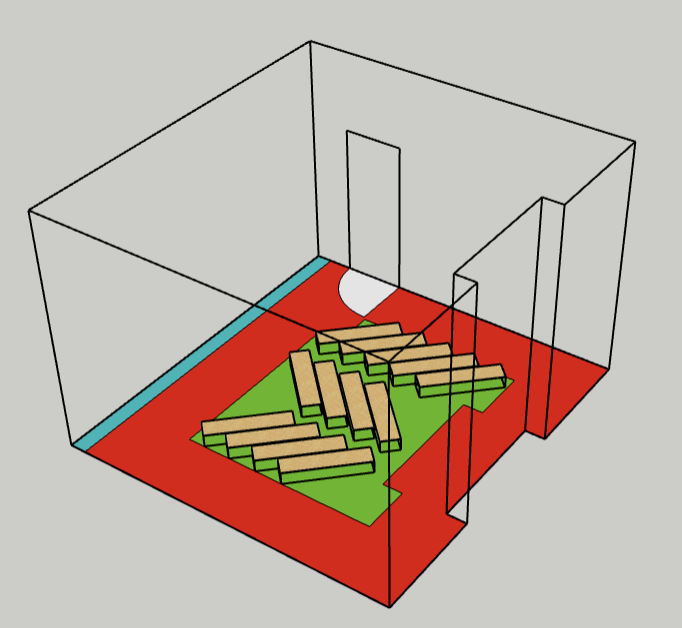

I looked at creating a circular drift of plinths with the intention to pull the viewer around the space. I feel like this concept has potential, but the current layout feels forced. Also, there are only 11 plinths rather than the proposed 25.

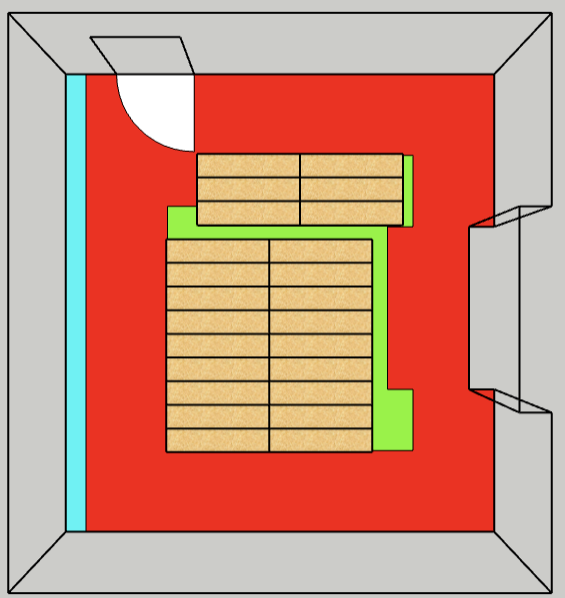

To improve upon the previous design, I looked at layering. By stacking the plinths on top of each other thereare differing levels which invite the viewer to explore the room and work closer. I feel that stacking is a crucial element to introduce. Not only does this drive interaction but also increases the number of plinths we can fit in the room (there are 17 in this version).

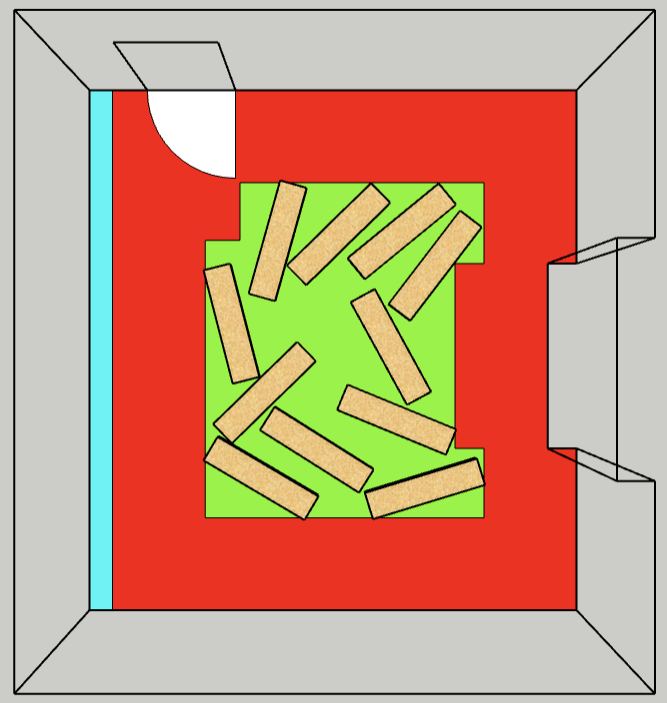

To explore this idea of drawing people through the space and thus the work on display, I introduced an additional walkway diagonally through the room. I feel this forced the plinths together in an awkward and squished layout. This may have worked better if the room was much larger. However, I like the enhanced differentiation of the levels, creating an almost ‘hills and valley’ aesthetic, which I feel could be introduce into the previous design.

To help visualise my Sketchup models I worked with Greg (another student) to mark out the room in the Box. This allowed us to move around the space and get a feel for how the plinths sit. I cut out 4 test plinths from some scrap to use as a mock up whilst we wait for the OSB order to arrive. I then experimented with rough placements of the plinths in the centre of the room and used a variety of previous work to help visualise how the samples will be presented.

I then experimented by stacking the plinths, with different levels, taking learnings from my Sketchup models. I also, considered layering series of work on different levels of plinths which helped to draw the viewers’ attention around the space.

I showed this mock up to Mark who liked the proposal, and we discussed that the plinths will be constructed and a final layout needs to be decided once we are in the space and have everyone’s samples.

The set up

As a team for setting up the show we divided the responsibilities. Mark and Oonah went through the student’s sample submissions and selected the best and relevant work to be placed in the show. Meanwhile, I worked with Sarah to select the most viable legs for the plinths and package all the work into crates.

A van then brought all the work and display materials to the Victoria Baths and we began unpacking.

Mark and Onnah led the curation of the show, whilst I assisted with moving and recording the day.

During the set up I spent most of my time observing how Mark approached the curation of the show. This was in my opinion more of a learning opportunity than a time to input my creative suggestions. Initially, Mark spent a while studying the room and working out the best way to position our display. We worked with the room’s layout utilising the focal point of the fireplace and the sunlight that came through the windows. We also needed to consider that the Textiles Course needed lots of wall space to lean boards against.

When building the plinths Mark and Oonah focused on systematically working out from the corner, ensuring a variety of levels were introduced. The plinths almost cascaded from tall to shorter as the structure expanded into the room. I observed the importance of these levels to help guide the viewer around the display, but also how leaving negative space allowed the display to breath. Moreover, the shadow from the boards in these negative spaces created contrast and framed the display.

One of the main takes aways from setting up the plinths was not being afraid to adapt and change any pre-existing plan. Although, we had created proposed layouts and pre-determined heights for the legs of the plinths, when setting up these could be adjusted. Only when we arrived to the room could we truly gauge the best place to set up the display. Also, we had produced legs in three differing heights to support the plinths, but Mark turned some legs on their sides to create very low to the ground plinths.

When curating the work,Mark and Oonah started with the larger pieces and then placed the smaller ones throughout. This ensured that the idea of a journey and exploration of the display was consistent with the setup of the plinths. Once again I found that the constant moving and adjusting of the work was important to hone the show, best presenting each individual's pieces as well as producing a cohesive showcase.

The final show

At the Private View, I spent most of the time on our stand talking to the visitors. The demographic that night was mainly other makers and creatives in the contemporary craft industry. My target was to communicate the aims of the sample exhibition in a brief few sentences. Additionally, I then had to explain my work and the intentions behind it. I found this harder to begin with as I didn’t know how much detail to include during many of the brief interactions with visitors. However, during the evening I got into a flow and found key words and phrases to articulate my ideas. Due to the type of visitors that night, the understanding of process and material was at a level where I could focus on key details of my own practice and didn't need to focus on explaining every detail.

Over the course of the evening, I spoke to some notable figures, which was good experience of speaking to different people in industry. For example, one lady was from a galley with a medieval armours collection which meant that I could discuss my inspirations and narrative behind my work on a deeper level. Another, had worked in a hand forming sheet metal workshop, resulting in a discussion on process.

Overall, the night gave me first-hand experience of talking to a variety of people in the craft industry.

During the weekend I spent time on our stand talking to the general public about the exhibition. This was a very different experience, where I spent much more time explaining the purpose of a sample show and how the collective group had produced the work. This difference showed me that I need to adjust how I communicate my ideas to people with differing levels of understanding of process and creative practice.

Thoughts on the display

What went well

· Lighting provided a nice balance of highlights and shadows

· Visitors liked the breadth of materials and processes on display

· Visitor were impressed with the quality of work displayed especially considering the short timeframe of the project

· The display encouraged the viewer to move about and explore the work

· Having multiple pieces of in the show allowed the showcase of different elements of our project such as varying processes

· Lack of information on the display encouraged interaction with the invigilators allowing them to directly discuss the work

· The zine provided additional information and a resource for us to explain others practice in more detail

What needs improvement in the future

· The signposting outside of the room needed to explain what the visitors were entering into

· The poster had too much information on it and was too small

· The placement of the zine made it inaccessible

· The height of the plinths was a little too low for some to see, especially the older viewers who struggled to bend down to get a closer look

· There needed to be better communication between the different courses showing, having a group of invigilators that can explain everyone’s work would result in even opportunities and a better representation of the university as a whole

· Having a uniform policy of business cards and access to individuals’ information so that it provides an equal showcase

· Having a clear link to peoples contact information and a choice of my portfolio or Instagram

· Providing the invigilators with a prompt list so and FAQs so that they feel more comfortable answering questions and relaying the important information

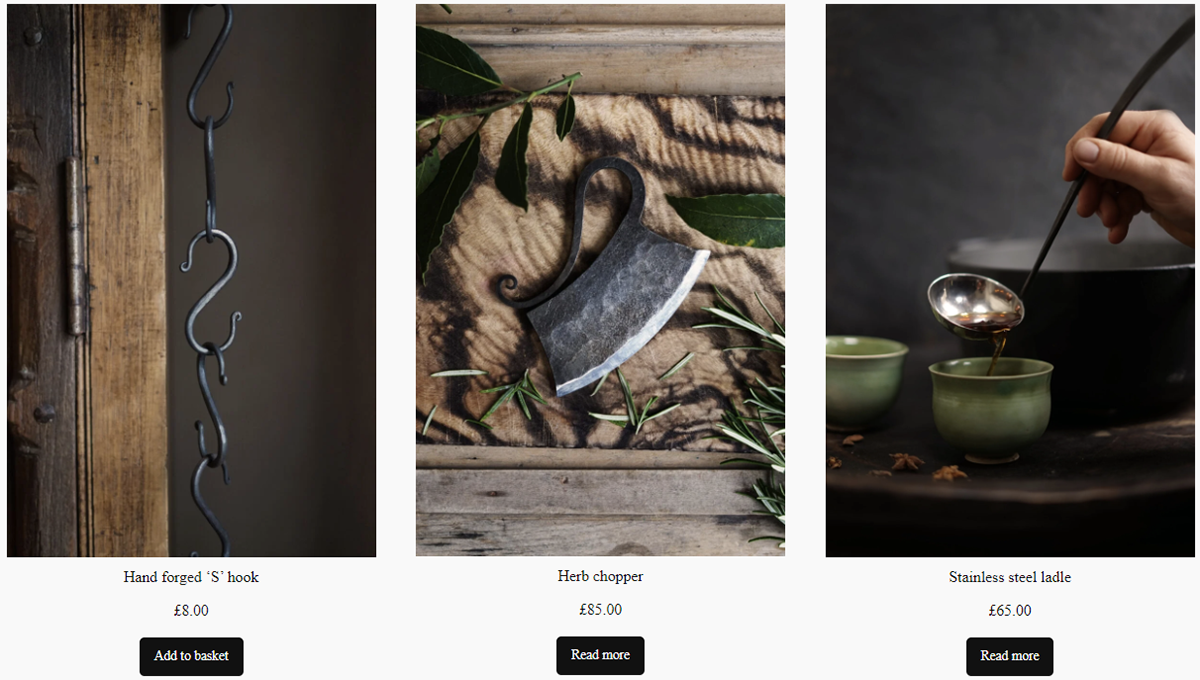

Talking to the other Makers

Over the weekend I got the opportunity to go and talk to all the different makers that were also exhibiting and selling their work. This gave me an insight into the type of work that was shown at GNCCF as I hadn't previously had the chance to attend. I found that there was a large variety of mediums and inspirations behind the different works, but the people that I focused on were the metalsmiths. I was drawn to a lot of the work by the silversmiths; despite not working in precious materials, I found their exploratory approach to process and surface finish inspirational. Additionally, there were a few blacksmiths showing, however their work was very commercial gift items. I utilised the time to speak to them about their practice and discussed the transition from education into the industry.

When speaking to the makers I didn't take any photos as I felt that spending as much time as possible actually speaking with them was much more beneficial to me than focusing on their work.

Tomas Bromley from Burnt Orchid:

During our conversation we discussed the balance between his cutlery range (the work he brough to GNCCF) and his more traditional artist blacksmithing work (gates and railings). He explained that his cutlery range was more of a side project and a hobby that he explores to fuel his creative drive. Whereas the artist blacksmith work was the core part of his business that made him more of a consistent income. This balance is very common amongst blacksmiths in the current market that I have spoken to, showing that as a self-employed maker it is important to keep a steady and reliable income to ensure passion projects are possible.

This balance between steady income and passion project is something that I have been thinking about for when I graduate. Currently I believe that finding somewhere be employed in a metal workshop is an important goal, so that I can continue explore my practice without the stress of producing products for a consistent income.

Angus Wood Blacksmith:

Angus gave me many useful resources during our conversation. One of which was the supplier he uses to buy steel from: https://www.fhbrundle.co.uk/?srsltid=AfmBOoo2VLq6w_Q-wL3Cbpaui0si4_s-267G-F2Mg4xTVwk6I6LvYPSz

He mainly uses mild steel to produce his hooks and fire pokers (the products he was selling at GNCCF), and A2 tool steel to produce his knifes or any tools.

Additionally, he directed me towards the Blacksmith Group on Facebook as a very good resource for UK based blacksmiths to share information and events.

On top of the resourses, he provided he gave me advice on areas to focus on whilst transitioning from a student into the industry. He recommended practicing making tools and exploring as many different processes as possible whilst still having access to a workshop full time. He also spoke about reaching out to many different blacksmiths and finding out their process, and not putting too much emphasis on one way of working. He found that his mentor focused very heavily on using a welder and didn't appreciate the artform of working in a more traditional forging process.

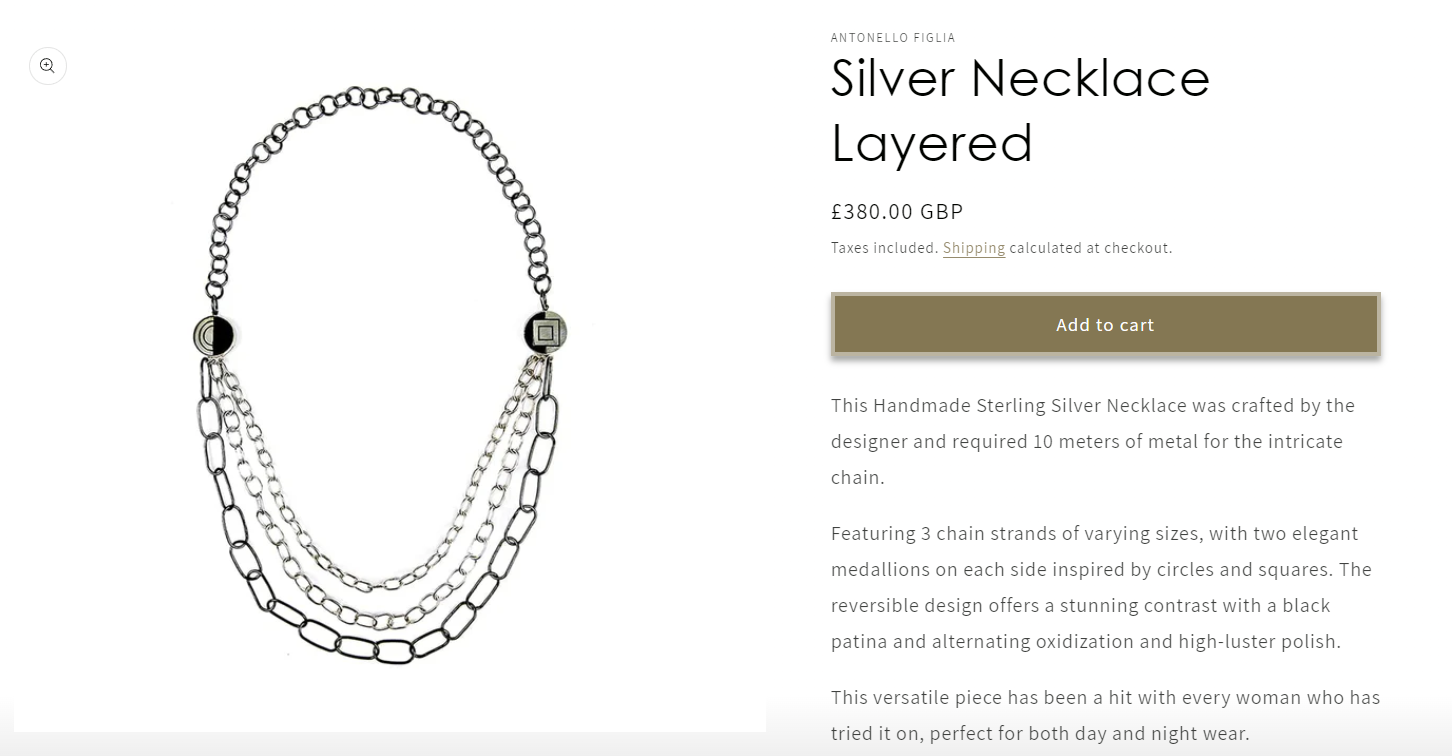

Antonello Figlia

I was drawn to Antonello's stand by his "Silver Necklace Layered" piece which was a simple 3 stacked chain necklace. During our discussion we explored the process of chain making and why I was so drawn to this piece. We found that I appreciated the simplicity and focus on well-crafted variation of chain styles. This is something that I wish to explore further in my own chain making practice, the introduction of multiple sizes and styles.

Morvarid Alavifard

Morvarid had a variety of different raised vessels on her stand made from silver, copper and aluminium. She explores hand engraving onto these vessels and focuses her practice on the surface finish. She worked with the material creating a conversation between maker and metal. We discussed her process of using heat and quickly quenching her work to encourage patina. She explained the beauty of the unpredictability of adding surface finishes in this way and allowing the material to speak for itself, rather than trying to control every aspect.

I found the variety of surfaces finishes she had achieved through this process inspiring and believe this is an area I should explore further in my own practice.

Tom from Studio Lehern

During my discussion with Tom, he talked me through the way he transitioned from student into finding a place of employment in the industry. He currently works with Solus ceramics where his focus is to bring architects closer to the materials they use. However, his main passion is creating which he channels through his time at Studio Lehern.

He spoke about how he spent his third year creating a list of everywhere he wanted to work, both alongside individuals as well as larger studios and companies. He also created a larger list of everywhere that was doing work in the industry around ceramics in and around Manchester. From this list he contacted as many people as possible, some of which offered him the opportunity tovisit their studio. Additionally, it gave him a feel for what was available in the market at the time. Furthermore, it was a good way to get his name out and start to build connections.

As I currently don't fully know where I see myself working after I leave university, I think that this would be a good process to undergo.